Machine Repairs

Prime Tool Rebuilders provides on-site machine field service repair throughout the United States. Our usual response time to service is about 24-48 hours. A machine that is ‘down’ is a problem that needs solutions as quickly as possible. Reduced productivity, decreased capacity, and revenue lost. It is paramount that you get prompt, expert service to diagnose and fix the problem!

- Work on Any Make/Any Model of Machinery

- Machine Tool Evaluation/Inspection

- On-Site Machining Service

- Alignment/Leveling Systems,

- Including: Rotalign, Boralign, and P-Level

Whether machine repairs are made at your location or back at our shop, our knowledgeable, experienced service technicians will troubleshoot what is wrong, provide a plan, and make the repairs needed to get you up and running again.

- Lathes, Turret Lathes, Mills, VTL’s

- Horizontal Boring Mills

- Horizontal Machining Centers

- Multi-Axis (B-Axis) Turning Centers

- 5-Axis Machining Centers

- Bridge and Gantry Mills

- Laser/Plasma Cutting Machines

- Vertical Machining Centers

- Multi Spindle Turning Centers

- Double Column Machining Centers

- Universal Milling Machines (5-Axis)

- Hobbers

Brands we Service

- Abb Group

- Allen Bradley

- Atlas Copco

- Atrump

- Baldor-Reliance

- Barber-Colman

- Blanchard

- Bodine

- Bosch Rexroth

- Bourn & Koch

- Bridgeport

- Bullard

- Cincinnati

- Daewoo

- Danaher Corp

- Danfoss

- Demag

- DMG-Mori

- Doosan

- Eaton

- Enshu

- Ex-Cell-O

- Fadal

- Fanuc

- Fluke

- Fuji

- G&L

- Gleason

- Grob

- Haas

- Hardinge

- Heald

- Heidenhain

- Hermle

- Honeywell

- Hurco

- Huron

- Ishida

- Kearney & Trecker

- Kitamura

- Kollmorgen

- Landis

- Lodge & Shipley

- Lucas

- MAG

- Makino

- Mazak

- Mitsubishi

- Mitsu Seiki

- Modicon

- Moog

- Mori Seiki

- Nakamura

- Nachi

- Niigata

- NTC

- Parker Hannifin

- Okamoto

- Okuma

- Okuma Howa

- Reliance

- Rockwell Automation

- SPX Corp

- Siemens

- SNK CNC

- Starrett

- Teco-Westinghouse

- Telemechanique

- Thompson

- Toshiba

- Toyoda

- Waukesha (SPX Corp)

- Westinghouse

- Yaskawa

- and more…

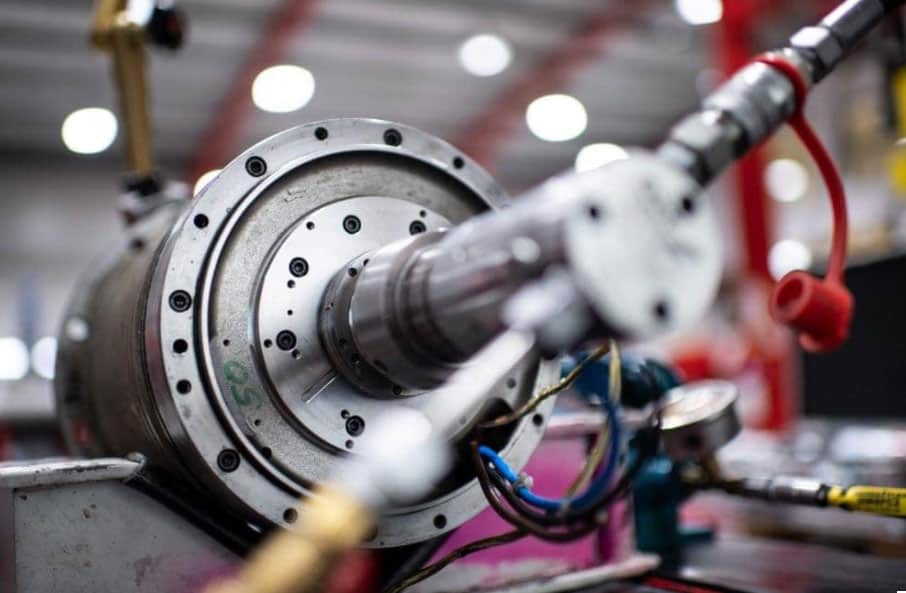

Machine Tool Rebuilds

Machine tool rebuilding involves a detailed process to assess, measure, dismantle, catalog, research, scrape, grind, paint, fit, align, and test run. Hydraulics, pneumatics, electrical, mechanical, safety – all aspects of machine operation come under the highest levels of examination to insure like-new performance and accuracy.

You can rely on Prime Tool Rebuilders to get your machine tool rebuild job done right—on time and on budget:

- Complete machine tool disassembly/reassembly

- Way Work (including scraping, alignment, and linear way replacement)

- Expert part reconditioning and/or, machining, rebuilding, sourcing

- Work-holding Chuck repair and replacement

- Ball Screw Repair and Replacement

- Motor repair and replacement

- Spindle Repair and Rebuild

- Hand Scraping

- Grinding

- Drives Upgrades

Machine Tool Retrofits

Machine tool retrofits most often go hand in hand with machine repair or rebuild projects. A CNC Control Retrofit empowers good old machines to do even more, with additional functionality and restored reliability.

Retrofits & Modifications

Specifically designed for your machine, our retrofit solutions help:

- Improve productivity

- Expand capabilities

- Energy savings

- Extend machinery life

- Assure machine safety

Whole machine assessment (mechanical, electrical, hydraulic, pneumatic)

- Panel building and re-wiring

- Complete retrofit integration

- Follow-up training and documentation (if requested)

Retrofit solutions that improve reliability and productivity and prolong machine life are obvious ways to achieve bottom line improvements. But the possibilities go far beyond that. Expanding the capabilities of your machines will open doors to new applications and business without investing in new equipment.

We can also provide customers with a full range of energy saving solutions, from simple heater band upgrades to Variable Frequency Drives (VFDs) that reduce energy consumption.

Preventive Maintenance Programs (PMP)

Whether you have an existing preventative maintenance program or need one developed, our team of experts will review your current processes to collect, examine and leverage data to identify the changes necessary for increased uptime in your facility. Then our maintenance technicians will get to work, executing your preventative maintenance plan (PMP) and delivering measurable results.

- Experienced preventive maintenance techs

- Program service for CNC and Manual Machines

- Control /drives /electronic system fine-tuning & troubleshooting

- Mechanical /hydraulic /pneumatic repairs

- Cooling system flush and clean service

- Precision leveling & alignment

- Ball bar analysis (tests accuracy and repeatability of your machine tool)

- Vibration analyzer

Preventative maintenance can also include (but is not limited to) the following:

- Change fluids

- Clean filters

- Check automatic tool changer alignments

- Check automatic pallet changer alignments

- Change CNC control backup batteries

- Ball screws and end bearing checks

- Gib and slide checks/Way wiper checks

- Check axis backlash

From aerospace to automotive, machining to manufacturing and just about every industry in-between, our highly cost-effective machine tool repair & support services are tailored to your needs with dedicated Mechanical, Electrical and Software engineers who can provide the best maintenance solution for you!